ABOUT US

WHY MAGNADRIVE?

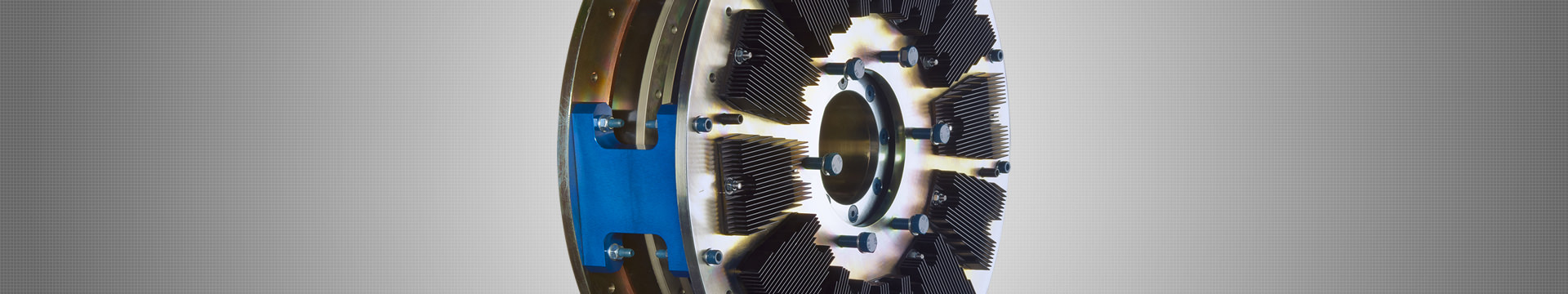

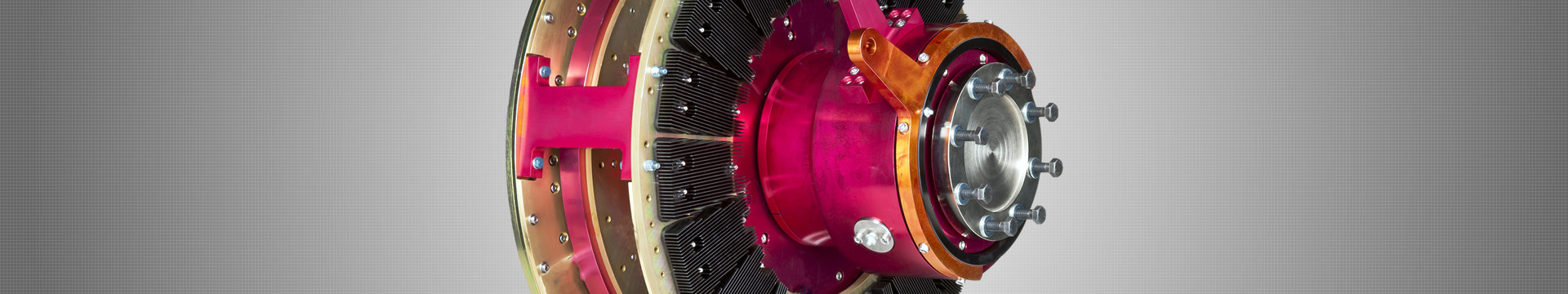

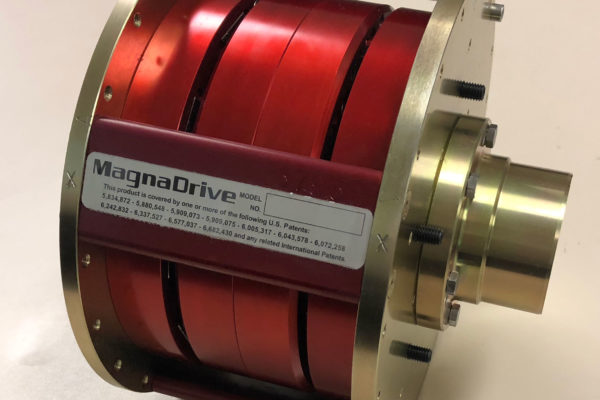

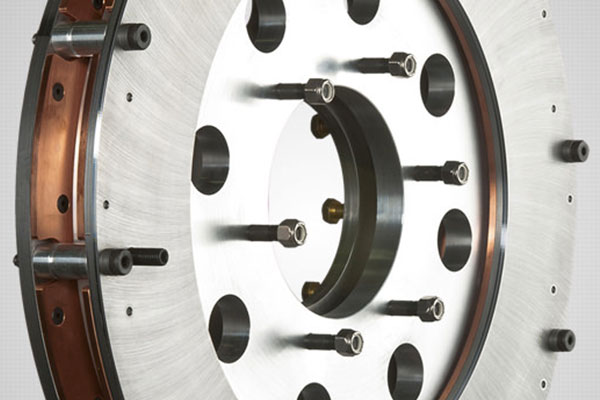

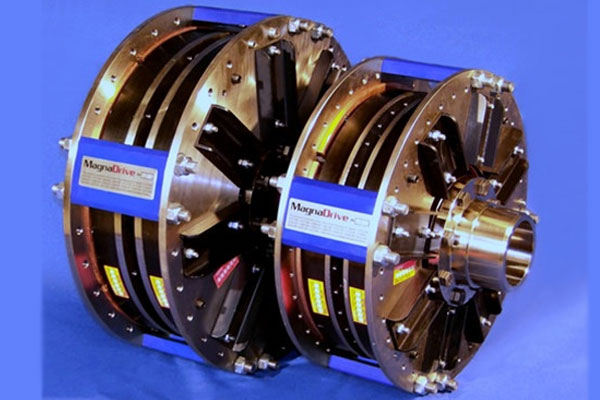

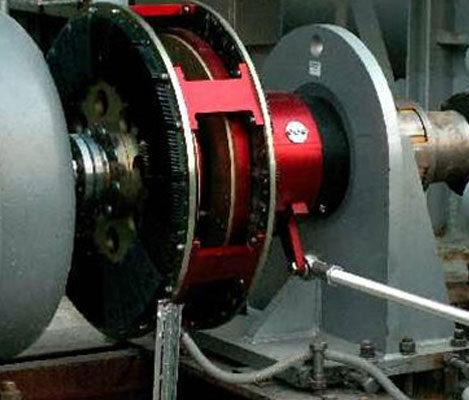

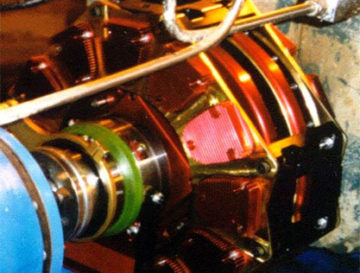

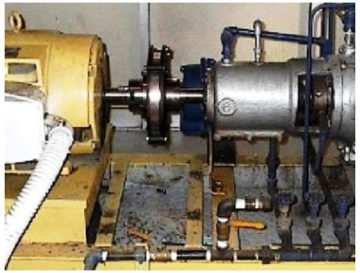

MagnaDrive couplings and Adjustable Speed Drives replace the physical connection between motor and load with a gap of air. This air gap eliminates harmful vibration, wear and tear, enhances energy efficiency, increases motor life and protects equipment from overload damage.

Some of the features and benefits of this technology include: MagnaDrive’s revolutionary disconnected torque-transfer technology reduces your total cost of ownership by lowering maintenance and operating costs, increasing process availability, and improving system reliability.

PRODUCTS

Offices

Worldwide

Refineries &

Operations

Satisfied

Employees

Awards &

Recognitions

Total Cost of Ownership

When compared to alternative drives or constant torque couplings MagnaDrive products offer:

- Increased process system reliability.

- Lower maintenance cost for motor, seals and bearings.

- Reduced operational downtime.

- Substantial energy savings.

- Extended life of critical productive assets.

| Voltage | Rated Power @ 1800 RPM | Permanent MagnaDrive (PMD) | Hydraulic Fluid Coupling (HC) | Variable Frequency Drive (VFD) |

| 380 V | < 150 KW | Efficient Expensive | Not Efficient Expensive | Efficient Not Expensive |

| 3.3/6.6 KV | 150 – 460 KW | Efficient Not Expensive | Not Efficient Expensive | Not Efficient Expensive |

| 3.3/6.6 KV | 460 KW – 3000 KW | Efficient Not Expensive | Efficient Not Expensive | Not Efficient Expensive |

| 3.3/6.6 KV | > 3000 KW | Under development | Efficient Not Expensive | Not Efficient Expensive |

VFD, Permanent MagnaDrive, and Fluid Coupling for Power

In the current market, VFD’s are dominating under 150kW for its price, efficiency and performance. Permanent MagnaDrive couplings, (PMD) is dominating over 150kW up to 460 kW for its price, efficiency and performance. With applications over 460 kW up to 3000 kW, PMD and Hydraulic Fluid Couplings are competing with each other. Hydraulic fluid couplings, (HC) are dominating applications over 3000 kW.

The Chart below shows a comparison of PMD products for the power range of 150 kW – 460 kW.

ASD product Comparison for 150kW – 460 kW @ 1800 rpm

| Power Range: 150kW – 460 kW (200HP – 600HP) | Permanent MagnaDrive (PMD) | Variable Frequency Drive (VFD) | Hydraulic Fluid Coupling (HC) | Note |

| Product Efficiency | 95 ~ 97% | 96 ~ 99% | 83 ~ 87% | VFD’s loss due to heat is 5 ~ 10%. |

| System Efficiency | 95 ~ 97% | 91 ~ 94% | 90 ~ 85% | |

| Energy Saving | Shaft Power x speed^2 ÷ Magna Efficiency | Shaft Power x speed^3 ÷ VFD Efficiency | Shaft Power x speed^2 ÷ Fluid coupling Efficiency | Based on shaft power basis. |

| Maintenance cost | 3% | 20% | 15% | MagnaDrive product structure is a simple. |

| Life Expectancy | Over 30 years | 10 years | Over 30 years | PMD provides vibration reduction that contribute life extension. |

| Capital Investment Cost | Low | Medium | High | |

| Space required (distance) | 0.1 ~ 0.9 meter | 5 ~ 10 meter | 1.5 ~ 2.5 meter | |

| Estimated ROI | 0-3 Years | More than 3 years | More than 3 years |

PMD products and Fluid couplings are frequently used for fans and pumps over 460 kW up to 3000 kW. Below shows the comparison between PMD and HC.

Permanent MagnaDrive vs Fluid coupling vs VFD over 460 kW up to 3000 kW.

| Model | Hydraulic Fluid Coupling (HC) | Permanent MagnaDrive (PMD) | Variable Frequency Drive (VFD) |

| How it works & principle of energy saving | Saves Energy by varying the fluid amount between driving and driven impeller. This controls the load side (driven side) speed resulting in energy savings. | Saves energy by varying the air gap between driving and driven magnet rotor, This controls the load side (driven side) speed resulting in energy savings. | By varying the frequency and voltage supplied to the electric motor. |

| Main components | Fluid coupling, heat exchanger, actuator, cooling water line, working oil line. | Magnetic coupling, actuator. | Electrical control cabinet. |

| Pros | Very good for speed control on high speed, very large capacity applications over 10,000 kW motorsincluding turbines, Ships etc.. | Reduces vibration significantly because of torque transfer through an air gap. Up to 80% vibration reduction is possible. Proven to extend the life of bearings, seals and rotating equipment, forgiving on misalignment (25/100mm). Very good for process control, provides excellent starting times. Provides a cushion start. Low and short inrush currents from the motor leads to extended motor life | Reduced energy consumption. Easy starting and stop conditions. |

| Cons | Low efficiency at low speed. Electricity consumption on oil cooling pump. The cost of installation is high. The cost of periodic maintenance is very high. Environmental concerns on oil that needs to be discarded. | Noise level is high (3600rpm, ~95㏈) (1800rpm, 87 ㏈ ) | Can affect power quality of power supply.. Harmonic distortion from VFD can cause bearing fluting damage bearings. Requires large foot print. |

| Installation Space (distance) | 1.5~2.5 M | 0.1~0.9M | 3.0M or more |

| Life | 30 years | Over 30 years | 10-20 years |

| Maintenance | Needs significant maintenance every 5~7 years. | Needs moderate maintenance every 5~7 years. | Needs high maintenance every 5~7 years. |

| Delivery | 8~10 months | 2~3 months | N/A |

| Bearing, seal, equipment life extension? | No, Fluid coupling does NOT extend equipment life. Causes higher stress due to vibration and misalignment. This leads to a lower life expectancy for bearings, seals and rotating equipment. Increased friction due to vibration can also cause system power loss. | Yes, PMD couplings extend the life of rotating equipment. Due to air gap, reduced vibration and a higher misalignment tolerance the life of bearings, seals, and equipment is extend. | No, VFD does NOT extend the life of rotating equipment. Instead it may cause bearing fluting over time leading to shorter electric motor life. |

| Installation | Requires laser alignment between motor and the load side. | Even with a relatively big misalignment, PMD ASDs can operate with no problem and eliminate vibration and stress caused by misalignment because it transmits torque by non-contact through an air gap. Can be used for almost any kind of industrial motor. | Requires high level of electrical experience for full electrical system integration. There is no alignment benefit at all. |

| Operation, Maintenance | There exists multiple unstable operating points. Spare parts are expensive and maintenance costs are very high. There are cavitation and vibration issues. Frequent oil leaks are a very common problem and always troublesome. Frequent damage to bearings and seals. No protection against overload situation | Energy savings and is a Green product. Very efficient torque transmission. Very simple operation and maintenance. Reduces vibration dramatically Extends the life of bearings, seals and rotating equipment. NO EMI (Electromagnetic Interference). Low inrush current contributes to increased motor life. Can operate at the most efficient operating point | Moderate periodic maintenance during operating lifetime. Most VFDs require bus capacitor replacement every 5-7 years. |

| System efficiency and energy saving | Efficiency is either average or below average. Energy being wasted due to increased load when controlling fluid movement. | Efficiency is very good, about 97%. No efficiency loss due to any accessory equipment. Process control can be done easily just by changing air gap. Energy can be saved due to load reduction on motor. All MD ASDs provide low and short inrush current that not only protects motors but also contribute energy savings. | Very good efficiency when operating a high motor load but efficiency decreases with decreasing motor load. |

| Sweet Spot | 460KW ~ 3000kW, especially over 3000 KW | 460KW ~ 3000 KW | No sweet spot for this power range |

| Price | Hydraulic Couplings are price competitive for 460KW up to 3000KW. | MagnaDrive (PMD) is price competitive with HC for 460 KW up to 3000 KW. | Price is NOT competitive for this power range (extremely high price). |